For industrial furnaces, which are said to account for 50% of energy consumption by the entire industry, technological innovation is always required to respond unerringly and quickly to

needs of the times. We commit ourselves to satisfy our customers and live up to society’s trust, promoting the following initiatives under three principal policies: preservation of

consistent material quality, energy saving and productivity improvement.

Continuous steel pipe heat treatment furnace

To pursue quality:

-

Reduced decarburization with appropriate atmosphere

gas - Reduced formation of coarse grains

- Measures against transfer flaws and flange defects

To promote energy conservation

-

Process without acid pickling for environmental

protection and cost reduction -

Energy Conservation and reduction in CO2 by using

regenerative burner -

Effective utilization of generated heat reaction by

using built-in type gas generator

To improve productivity

- Cast resistor elongate electrical heater’s life

-

Automatic left / right pay-off control of work interval

lowers work load -

Anti-momentary voltage drop measure (secure power

supply unit) realizes steady operation and protection of

works in the furnace

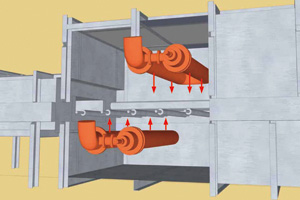

Continuous steel pipe heat treatment furnace : cooling zone

Continuous steel pipe heat treatment furnace : heating zone

Built-in type gas generator

Cast resistor